every. packaging

every. delivers plant-based frozen meals directly to consumers, leveraging robust corrugated packaging to ensure product integrity during transit. Their packaging approach prioritizes minimalist branding and functional materials tailored for direct-to-consumer frozen food logistics.

Packaging Portfolio

every. employs a multi-layered packaging system optimized for frozen food delivery, featuring double-walled corrugated boxes for primary shipping and branded flexible pouches or retail cartons for individual meal portions. The use of kraft paper for internal cushioning enhances product stability and thermal protection. The packaging structure is designed to minimize damage during transit while achieving high brand visibility with minimalist, large-font branding. Material selection balances cost-efficiency, recyclability, and performance in cold-chain logistics.

The packaging consists of clear plastic pouches containing food items, with a visible logo and branding elements. The pouches are flat and smooth, with no fluted layers, indicating they are made from single-layer paperboard or a similar material. The overall appearance is clean and organized, with a focus on the contents inside. The outer packaging is made of crumpled kraft paper, providing cushioning and protection for the pouches.

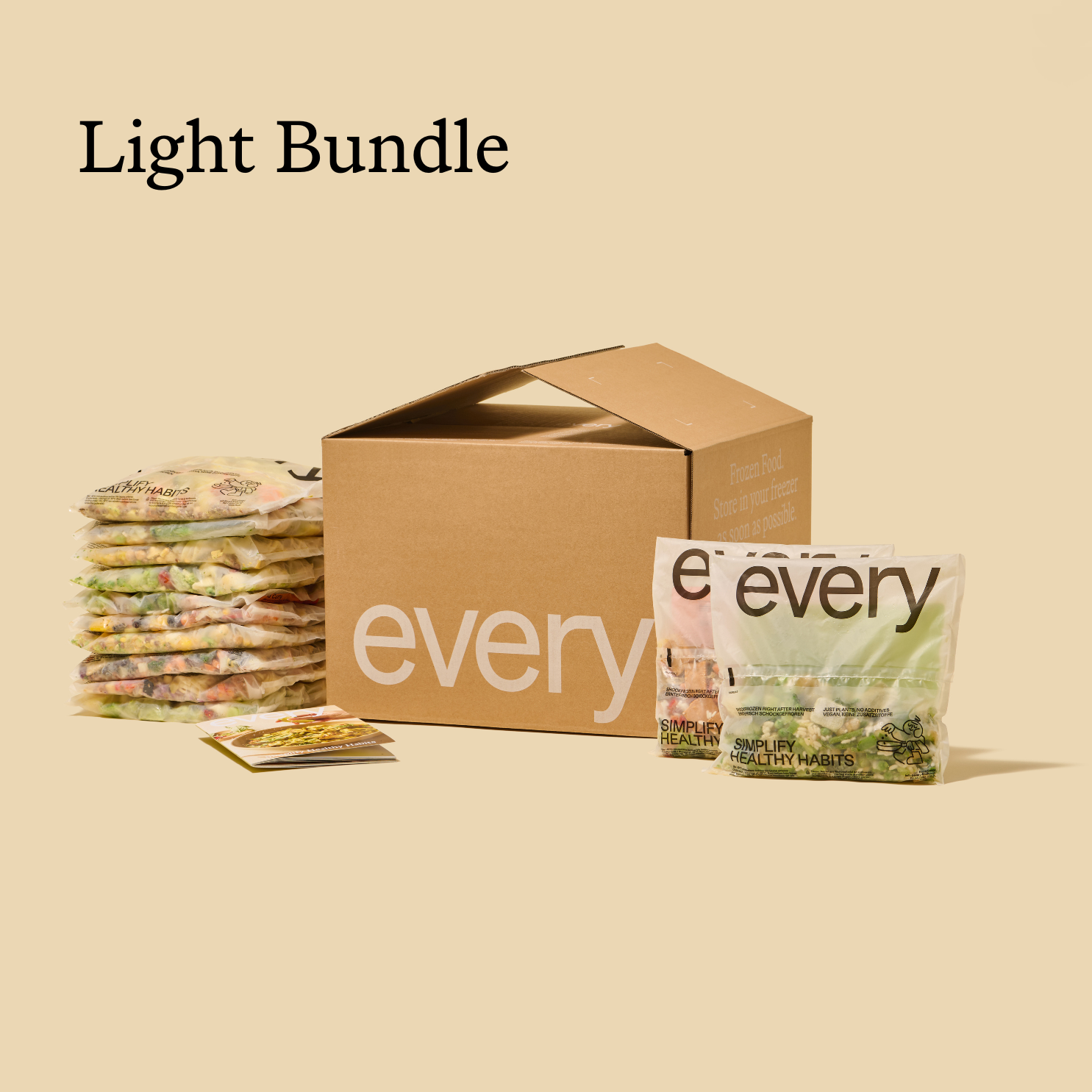

The image features a large, brown corrugated box prominently displaying the word 'every' in a large, white font. The box is open at the top, revealing several vacuum-sealed food packages stacked inside. The food packages are clear with colorful food images and the brand name 'every' printed on them. The box has visible fluted edges, indicating its corrugated construction, and appears sturdy enough for shipping. The overall arrangement suggests a bundle of food items ready for delivery.

The packaging consists of a sturdy corrugated box with a visible fluted inner layer. The box is primarily brown in color, typical of kraft cardboard, and features clean, precise edges. It is designed for shipping and has a robust construction. The box is shown partially open, indicating it is intended for easy access to its contents. Surrounding the box are several bags of frozen food, each with a clear plastic exterior, showcasing the product inside.

The packaging consists of a brown corrugated box prominently featuring the word 'every' on its side. The box has visible corrugated edges when viewed from the side, indicating its layered construction. It is surrounded by several bags of products, which appear to be made of a flexible material, likely plastic or paper. The overall arrangement suggests a shipping box designed for delivering multiple items. The box has a sturdy construction suitable for shipping, with some signs of wear evident on the edges.

The outer box is a sturdy corrugated cardboard structure with visible fluted edges when viewed from the side. It is primarily brown/kraft colored and shows signs of wear from handling, such as slight crushing. Inside, there are several smaller folding cartons, each with a smooth, flat construction, featuring vibrant colors and branding.

The packaging consists of a brown corrugated box with a visible fluted inner layer when viewed from the side. The box has a sturdy construction suitable for shipping. It features a simple design with the word 'every' printed prominently on the side in a large, sans-serif font. The edges are clean, and there are no visible signs of crushing or wear, indicating it is in good condition. The box is open at the top, revealing contents inside, including bags and a cup of ice cream.

About the Brand

every. specializes in convenient, plant-based frozen meal subscriptions for health-conscious consumers. The company's packaging strategy is focused on operational efficiency, brand clarity, and safe delivery of temperature-sensitive products.

Founded in 2019 in Berlin, every. has scaled its direct-to-consumer model by utilizing sturdy corrugated shipping boxes and branded flexible pouches for individual meal portions. Packaging design reflects the brand’s minimalist ethos, balancing durability for cold-chain logistics with visual simplicity. The consistent use of kraft materials and clear branding supports both functional and marketing objectives in a competitive meal delivery market.

Key Differentiator: Distinctive minimalist aesthetic combined with robust cold-chain packaging tailored for vegan, frozen meal delivery.

Design System

Visual Style

Minimalist typography with large, sans-serif fonts; neutral kraft brown base paired with vibrant accent colors on internal pouches; overall clean and modern aesthetic.

Brand Identity

Prominent display of the 'every.' logo on all major packaging surfaces; use of consistent iconography and tagline placement to reinforce core values; cohesive color palette aligning with health and simplicity.

Packaging Design

Heavy reliance on corrugated cardboard for shipping durability, with flexible pouches for portion control and product visibility; emphasis on material recyclability and structural integrity for cold-chain delivery.

User Experience

Packaging is engineered for quick, intuitive unboxing and clear product identification; branding elements create a recognizable, positive first impression, supporting customer trust and repeat engagement.

Company Metrics

Business insights for every. based on available data

Market Positioning

Brand Values & Focus

Key Competitors

Target Market: Urban, health-focused individuals in Germany seeking convenient, nutritious, and vegan meal solutions via direct-to-consumer subscriptions.

Packaging Assessment

Overall Grade

Visual appeal and presentation quality

Packaging durability and protection

Eco-friendliness and recyclable materials

Cost efficiency and value for money

Packaging assessment for every. based on industry standards and best practices

Frequently Asked Questions

What types of packaging materials does every. use for their shipments?

every. primarily uses corrugated cardboard for outer shipping boxes, complemented by branded flexible plastic pouches for individual frozen meals. Additional cushioning is provided with kraft paper for product protection and thermal stability.

How does every. ensure the safe delivery of frozen products?

The company employs double-walled corrugated boxes with secure fluting and internal cushioning materials, designed to maintain product integrity and temperature throughout the cold-chain delivery process.

Does every. use sustainable packaging materials?

While corrugated cardboard is widely recyclable and kraft paper is compostable, the use of flexible plastic for meal pouches reduces overall sustainability. However, the packaging system reflects a balance between product protection and environmental impact.

Discover other Food & Drink companies

Explore more companies in the food & drink industry and their packaging strategies

PrepMyMeal

Food & Drink

PrepMyMeal is a food production company specializing in high-protein meal delivery services. They offer a variety of natural, nutritious meals designed for fitness enthusiasts and those seeking convenience in meal preparation.

ruf lebensmittelwerk kg

Food & Drink

RUF Lebensmittelwerk KG is a German food production company specializing in a variety of baking mixes and drink products. Founded in 1920, the company is known for its high-quality ingredients and innovative food solutions.

Terres de Café

Food & Drink

Terres de Café is a specialty coffee retailer based in Paris, France, known for its commitment to sustainability and high-quality coffee sourcing.